Artificial Intelligence Powered Renewables in Hydrogen Technology

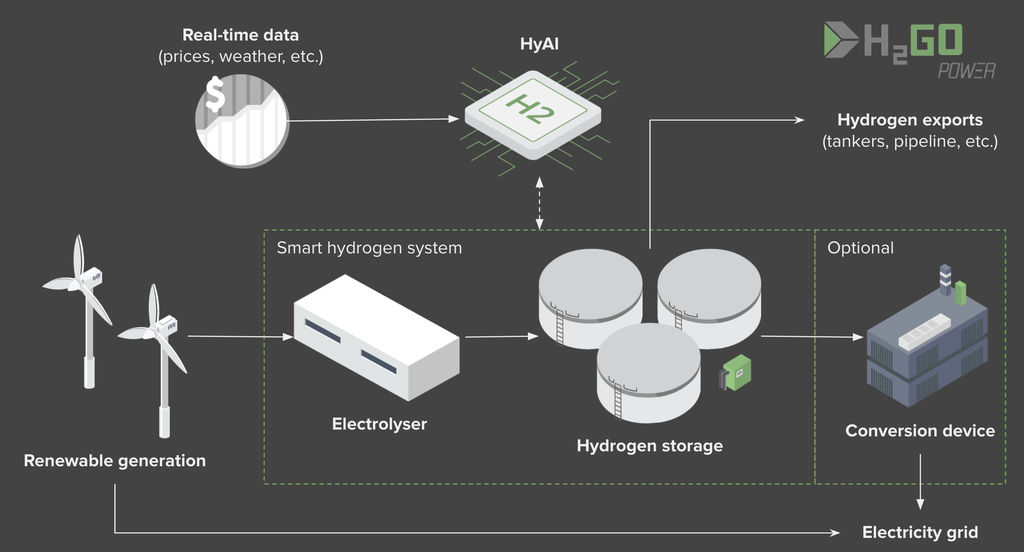

Hydrogen is the simplest element on earth—it consists of only one proton and one electron—and it is an energy carrier, not an energy source. Hydrogen can store and deliver usable energy, but it doesn’t typically exist by itself in nature and must be produced from compounds that contain it. The ability to convert excess green electricity into hydrogen is projected to be a “game-changer”, while AI algorithms – with their use within the ‘internet of things’, sensors and big data – can help stabilize central grids and increase dispatch efficiency.

AI can make energy management storage decisions based on its predictions of when energy will be most in-demand and the data it collects from real-time renewable energy sources and network conditions. Artificial Intelligence also has a part to play when it comes to maintenance. This makes an AI-centred system a potential game-changer. Shifting from an infrastructure heavy system to one centred on AI enables forecasting and control in seconds – not days – resulting in a grid that is more resilient and flexible when unforeseen events occur.

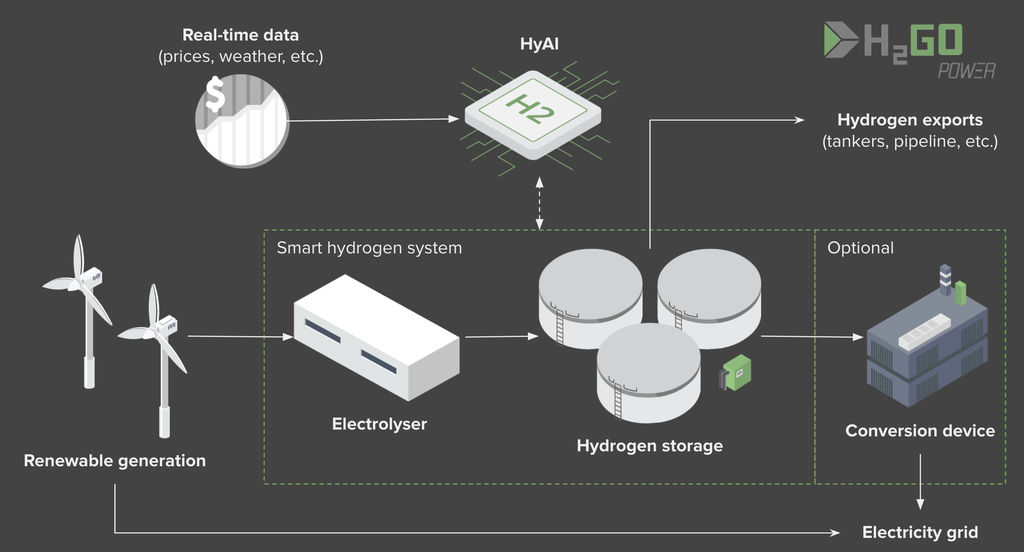

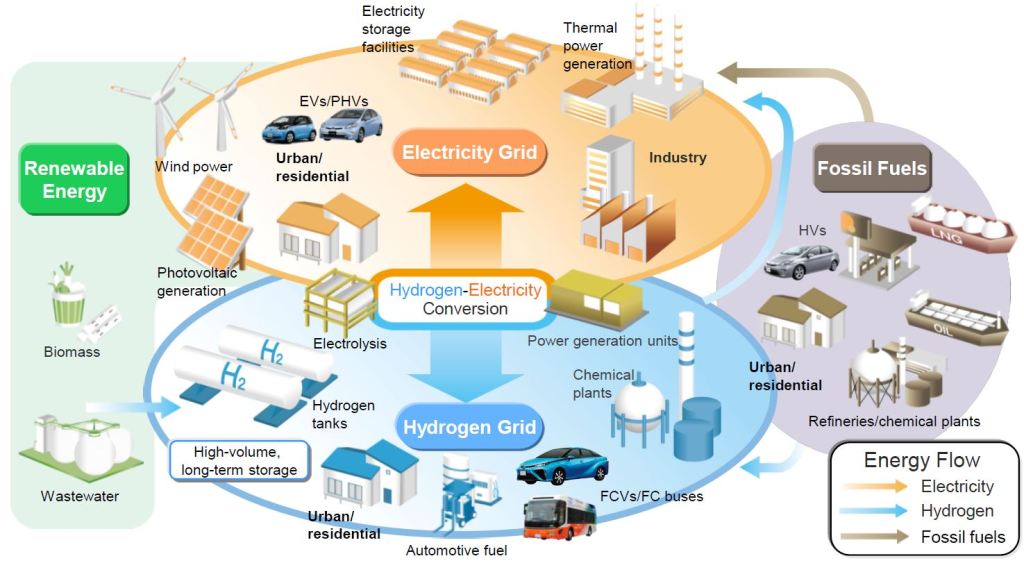

UK hydrogen storage provider H2GO Power is leading trialling of the use of artificial intelligence (AI) software coupled with hydrogen technology. The aim of the Hydrogen Artificial Intelligence (HyAI) project is to demonstrate the use of AI software integrated with hydrogen hardware in making data driven asset management decisions in real time and optimising renewable energy integration into the electricity grid. The AI platform acts as an energy management system, integrating data about the weather, electricity prices and grid management, with this then translated using its predictive algorithms to optimise the operation of the storage units by predicting both future power costs and user demands.

Currently, hydrogen production is expensive, not environmentally friendly, and makes no economic sense since it requires way more energy to produce a gallon of hydrogen than the energy content of the hydrogen produced. Hydrogen today is neither a green energy source nor is it’s use sustainable. While most hydrogen generation is done on a large scale at a central location, both distributed & localized hydrogen generation would reduce costs and provide a reliable fuel supply by producing hydrogen where its needed, like in electric cars, homes, & offices. At the moment the dominant method for production is what’s called steam reforming from hydrocarbons, where large industrial quantities are produced by heating natural gas (methane) mixed with water steam to separate the hydrogen from carbon.

The use of fossil fuels (gas) erodes the renewable/green advantage of hydrogen. This steam reforming is done with an 80% efficiency and accounts for 95% of all hydrogen produced in the world.

Making Hydrogen Cheap by Imitating Bacteria

Although there are several methods for biohydrogen production available, biohydrogen may be produced through either photosynthetic means like the algae example, or the fermentation process. In general, fermentative hydrogen production is more efficient than photosynthetic and can be equated to the production of alcohol by the fermentation of grapes (wine), barley (beer), potatoes (vodka), etc. The major difference being that instead alcohol as the product, we get Hydrogen instead.

Once hydrogen is produced as molecular hydrogen, the energy present within the molecule can be released, by reacting with oxygen to produce water. This can be achieved by either traditional internal combustion engines, or by devices called fuel cells. In a fuel cell, hydrogen energy is converted directly into electricity with high efficiency and low power losses. Widespread use of renewable green hydrogen fuel cell technology, both within electric vehicles and electronic devices, could rapidly reduce air pollution and our dependence on fossil fuels. Although governments are not yet fully committed to a transition, consumers are becoming increasingly conscious and frustrated. This is driving the demand for products developed using renewable energy sources.

In the energy business, people refer to hydrogen by an array of colors to as shorthand for how it was created.

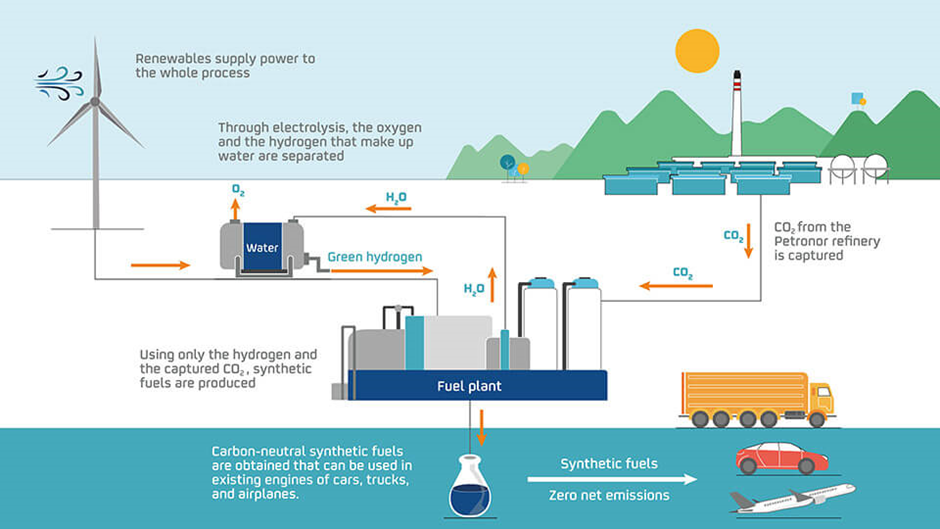

One may of making hydrogen is a process called electrolysis, when electricity is passed through a substance to force a chemical change — in this case, splitting H2O into hydrogen and oxygen.

Green hydrogen is when the energy used to power electrolysis comes from renewable sources like wind, water or solar.

Blue hydrogen is hydrogen produced from natural gas with a process of steam methane reforming, where natural gas is mixed with very hot steam and a catalyst. A chemical reaction occurs creating hydrogen and carbon monoxide. Water is added to that mixture, turning the carbon monoxide into carbon dioxide and more hydrogen. If the carbon dioxide emissions are then captured and stored underground, the process is considered carbon-neutral, and the resulting hydrogen is called “blue hydrogen.”

Grey hydrogen is made from natural gas reforming like blue hydrogen, but without any efforts to capture carbon dioxide by-products.

Pink hydrogen is hydrogen made with electrolysis powered by nuclear energy, which does not produce any carbon dioxide emissions. (Although nuclear energy creates radioactive waste which must be stored safely for thousands of years.)

Yellow hydrogen is hydrogen made with electrolysis from the energy grid. The carbon emissions vary greatly depending on the sources powering the grid.

Turquoise hydrogen is hydrogen produced from methane pyrolysis or splitting methane into hydrogen and solid carbon with heat in reactors or blast furnaces. Turquoise hydrogen is still in its nascent stages of being commercialized, and its climate-conscious value depends on powering the pyrolysis with clean energy and storing the physical carbon.